the problem

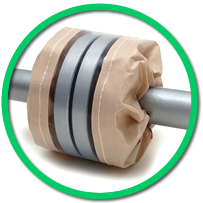

Flange Shields – Technoshields are designed to protect personnel and equipment,

deflecting and temporarily containing leaks and sprays of dangerous fluids (e.g. acid,

alkali, solvents, hot oil, hydrocarbons, etc.).

A correct use of Flange Shield – Technoshields systems helps create safer working conditions and save money by simply avoiding plant damage and personnel injury. Our Flange Shield is recommended for any pipeline, especially those with Teflon® or glass lining.

the solution

Applicazioni Tecniche is specialized in the design of tailor-made Flange Guards

Technoshields, to fit and comply with customer’s requirements.

Our technical office finds solutions for non-standard applications, unconventional sizes and any piping configuration.

Less risk with Technoshields

In Process Industrial Plants, Risk Reduction is the Goal: a simple evaluation proves that the value of risk of a fluid release in a pipeline is directly related to probability of the accident.

Flanges are sealed together to avoid outcome of fluid, however variables involved in effective tightness are multiple, stating appropriate material selection has been performed:

Torque

precise and accurate torque on bolts applied by operators: operators should understand and strictly follow guidelines for bolt torque

Alignement

a percentage of flanges result generally not aligned with the counter flange.

Thermal Cycles

operational temperatures for processes can be really high 300°C (580°F), but after the maintenance shutdown (cold cycle) leakages may occur.

Thermal elongation of bolts

metallurgists are always studying new alloys to limit permanent deformation of bolts due to higher temperatures (sometimes GR600 alloys are not enough).

Corrosion

some fluids show a very high corrosion rate which needs to be contained by passivation of gases or vapors.

Chemical fluids

in contact with human organism could generate irreparable damages. Environmental consequences for chemical substances releases are really costly.

Even if the probability of such event is low, consequences can be catastrophic in terms of human casualties, down-time, insurance prizes and environmental issues.

Flange Guards are cost effective solutions studied to minimize consequences in the event of pipeline spray-out. These can happen on flanges, valves, expansion joints or any other part of a process line.

Flange Guards are predefined covers to be installed on existing pipe parts during maintenance works, plant modification or even during operation so that, in the unattended event of fluid release, a shielding is provided to avoid high pressure spray or even toxic leaking.

This can be aimed only with a certified strength and a full chemical compatibility.

Mitigate effects of leakage with Technoshields

Can be installed directly on pipes

Do not need Plant Shut Down

Do not need modification of piping layout

Can be easily adapted to interferences